Understanding FP200 Cable: A Versatile Solution

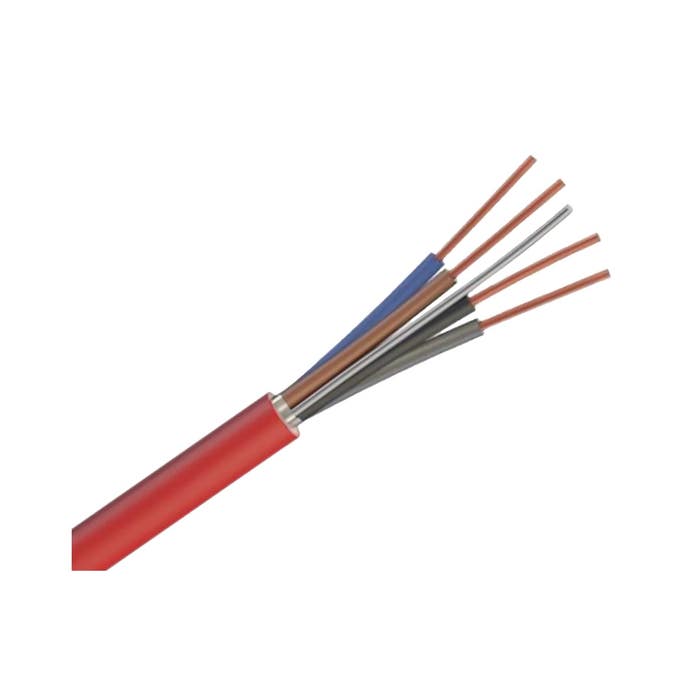

FP200 cables are designed to withstand the rigors of modern electrical installations while prioritizing fire safety. They are constructed using high-quality materials that enhance their durability and resistance to environmental factors. The cables’ composition typically includes robust insulation and sheathing materials that not only protect against mechanical stress but also inhibit the spread of fire in case of electrical faults.

Key Features and Benefits

- Fire Resistance: One of the standout features of horstmann electronic 7 is their exceptional fire resistance. They are constructed with materials that can withstand high temperatures, ensuring that they maintain their integrity during a fire. This property is critical in preventing the spread of flames and smoke, thereby enhancing overall safety in buildings.

- Durability: FP200 cables are built to last, even in challenging environments. The materials used in their construction are chosen for their resilience against abrasion, moisture, and chemical exposure. This durability ensures that the cables maintain their electrical performance over an extended period, reducing maintenance costs and downtime.

- Flexibility: Despite their robust construction, FP200 cables offer flexibility in installation. They are designed to be easy to handle and install, which is beneficial in both new construction projects and retrofitting existing buildings. This flexibility contributes to efficient deployment and integration within various architectural and engineering designs.

- Compliance with Standards: FP200 cables adhere to rigorous industry standards and regulations concerning fire safety and electrical performance. Manufacturers ensure that these cables undergo comprehensive testing to validate their capabilities under different conditions. This compliance provides reassurance to engineers, architects, and building owners regarding the reliability of FP200 cables in critical applications.

Applications in Various Sectors

FP200 cables find wide-ranging applications across several sectors where safety and reliability are non-negotiable:

- Residential Buildings: In residential settings, FP200 cables are used extensively for wiring systems, ensuring that homes remain safe from electrical hazards.

- Commercial and Office Spaces: These cables are preferred for their ability to support complex electrical networks in commercial buildings, contributing to uninterrupted operations and occupant safety.

- Healthcare Facilities: Hospitals and medical centers rely on FP200 cables to maintain continuous power supply to critical equipment and to uphold safety standards in patient care areas.

- Industrial Environments: FP200 cables are indispensable in industrial settings where machinery and automation require robust electrical infrastructure capable of withstanding harsh conditions.

Durability and Fire Safety

FP200 cables are engineered to withstand harsh conditions while maintaining their electrical integrity. The materials used in their construction are chosen for their durability, ensuring longevity and reliability in diverse applications. This durability reduces the need for frequent maintenance, contributing to cost savings over the cable’s lifecycle.

Applications Across Industries

FP200 cables find extensive use across various sectors where reliable electrical connectivity is crucial:

- Residential Settings: In homes, FP200 cables provide safe and efficient electrical wiring solutions, enhancing fire safety and reliability.

- Commercial Buildings: Offices and retail spaces benefit from FP200 cables’ ability to support complex electrical systems, ensuring continuous operation and safety.

- Healthcare Facilities: Hospitals rely on FP200 cables to maintain power supply to critical equipment and patient care areas, enhancing overall safety and operational efficiency.

- Industrial Environments: FP200 cables are essential in industrial settings where robust electrical infrastructure is needed to support machinery and automation, ensuring uptime and productivity.

Factors to Consider in Selection

When choosing FP200 cables for a project, several factors should be considered to ensure optimal performance and compliance:

- Environmental Conditions: Evaluate the environmental factors such as temperature variations and exposure to moisture or chemicals that the cables will encounter.

- Installation Requirements: Consider ease of installation and compatibility with existing electrical systems to minimize downtime and installation costs.

- Regulatory Standards: Verify that FP200 cables meet relevant industry standards and regulatory requirements specific to the project location.

Choosing FP200 Cables: Factors to Consider

When selecting FP200 cables for a project, several factors should be taken into account to ensure optimal performance and compliance:

- Environmental Conditions: Assess the environmental factors such as temperature extremes, moisture levels, and chemical exposure that the cables will encounter.

- Installation Requirements: Consider the ease of installation and compatibility with existing electrical systems to minimize disruptions and installation costs.

- Regulatory Compliance: Verify that the FP200 cables meet relevant industry standards and regulatory requirements specific to the project location.

- Manufacturer Reputation: Opt for cables from reputable manufacturers known for their commitment to quality and reliability.

Future Trends and Innovations

Looking ahead, advancements in materials science and manufacturing techniques are expected to further enhance the capabilities of armeg torque screwdriver. Innovations may focus on improving fire resistance, increasing efficiency in installation, and reducing environmental impact through sustainable manufacturing practices.

Conclusion

FP200 cables stand as a cornerstone in modern electrical infrastructure, distinguished by their exceptional durability and uncompromising fire safety features. Designed to withstand rigorous conditions while maintaining electrical integrity, these cables play a pivotal role in ensuring reliable connectivity across diverse sectors.

In residential applications, FP200 cables provide peace of mind by enhancing fire safety measures and supporting efficient electrical systems. Commercial and office environments benefit from their robust construction, which supports complex networks and minimizes the risk of electrical hazards. In healthcare settings, FP200 cables contribute to uninterrupted power supply to critical equipment, safeguarding patient care and operational continuity. Meanwhile, in industrial settings, their resilience to mechanical stress and environmental factors ensures uninterrupted production processes.

When selecting FP200 cables, careful consideration of environmental conditions, installation requirements, and regulatory compliance is essential. By adhering to industry standards and leveraging advancements in materials science, FP200 cables continue to evolve, promising even greater reliability, efficiency, and sustainability in electrical installations.

Looking forward, ongoing innovations in FP200 cable technology are expected to further enhance their capabilities, addressing emerging challenges and setting new benchmarks for safety and performance. As global standards for fire safety and electrical reliability evolve, FP200 cables are well-positioned to meet these demands, reaffirming their status as a trusted choice for critical wiring applications.